Flat wire surface area up to 60% more, means at higher frequencies flat wire support better skin effect, better for design higher current solutions, popular in UPS, solar, automotive, industry application.

Material Option:

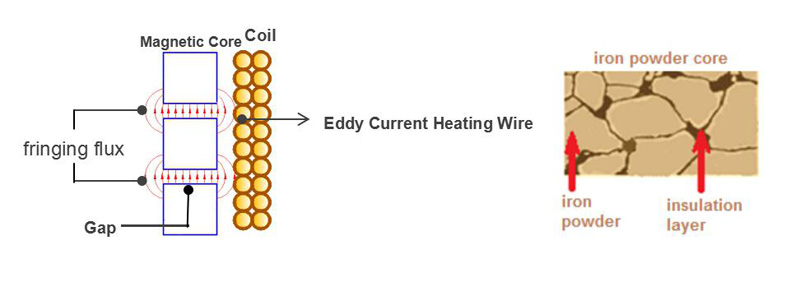

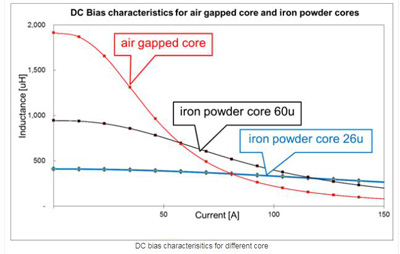

Powder cores are distributed air gap cores, with excellent inductance stability under both DC &AC conditions, high resistivity, low hysteresis & eddy current losses.

For different application request, we suggest different powder core:

1). For lowest loss inductor, the ultra low losses Kool Mμ Hf and MPP Powder cores are goods.

2). For the smallest core size in a DC Bias dominated design, the HIGH FLUX &EDGE powder cores with highest flux capacity are suggested.

3). For competitive cost, but reasonable low core loss & high saturation,Kool Mu powder core is good choice.

4). For low & medium frequency inductors and chokes, high saturation XFlux powder cores are much more economical, high saturation material (1.6T).

|

|

Kool Mµ |

Kool Mµ Max |

Kool Mµ Hƒ |

Xflux |

High Flux |

Edge |

MPP |

|

|

Allay composition |

FeSiAl |

FeSiAl |

FeSiAl |

FeSi |

FeNi |

FeNi |

FeNiMa |

|

|

Available Permeabilities |

14-125 |

14-60 |

26,60 |

19-125 |

14-160 |

26,60 |

14-550 |

|

|

Core Loss, 60µ(mW/cc) |

50KHz, 1000G |

215 |

200 |

120* |

575 |

250 |

150 |

165 |

|

100KHz, 1000G |

550 |

550 |

325* |

1280 |

625 |

375 |

450 |

|

|

Perm vs. DC Bias-60µ (Oe) |

80% of µ1 |

45 |

65 |

60 |

100 |

100 |

130* |

60 |

|

50% of µ2 |

95 |

130 |

115 |

170 |

185 |

205* |

105 |

|

|

60µ Temperature Stability - Typical % shift from -60 to 200°C |

6% |

3% |

5% |

4% |

4.50% |

2% |

2.50% |

|

|

Curie Temperature |

500°C |

500°C |

500°C |

700°C |

500°C |

500°C |

460°C |

|

|

Saturation Flux Density (Tesla) |

1 |

1 |

1 |

1.6 |

1.5 |

1.5 |

0.8 |

|

|

Frequency Response -60µ flat to... |

5MHz |

15MHz |

30MHz |

3MHz |

3MHz |

20MHz |

6MHz |

|

|

Relative Cost |

1x* |

2x |

2x |

1.2x |

4x-6x |

5x |

7x-9x |

|

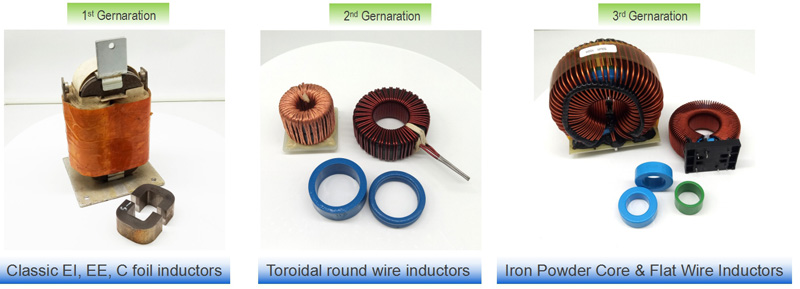

Inductors Advantage Comparing:

|

|

Classic EI, EE, C foil inductors |

Toroidal round wire inductor |

Flat wire toroidal inductor |

|

Component |

EI,EE,C Core |

Toroidal Core |

Powder Core |

|

Toroidal Wire |

Toroidal Wire |

Flat Wire |

|

|

Power range |

20KVA ~500KVA |

|

3KVA ~ 100KVA |

|

Material use efficiency |

Poor |

Good |

Excellent |

|

Magnetic field homogeneity |

Poor |

Excellent |

Excellent |

|

Manufacturing Process |

Hard |

Easy |

Easy |

|

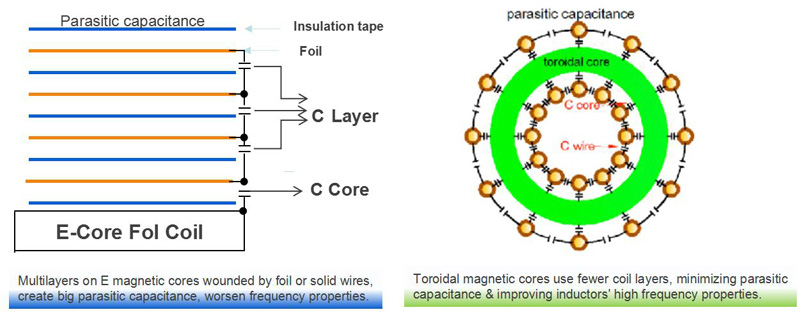

Parasitic capacitance |

High |

Low |

Very low |

|

Insulation reliability |

Poor |

High |

Very high |

|

Cooling efficiency |

Poor |

High |

High |

|

High Power coil losses >100kVA |

Good |

Medium |

Poor |

|

DCR high power >100kVA |

Excellent |

Good |

Poor |

|

Filling factor |

Good |

Good |

Medium |

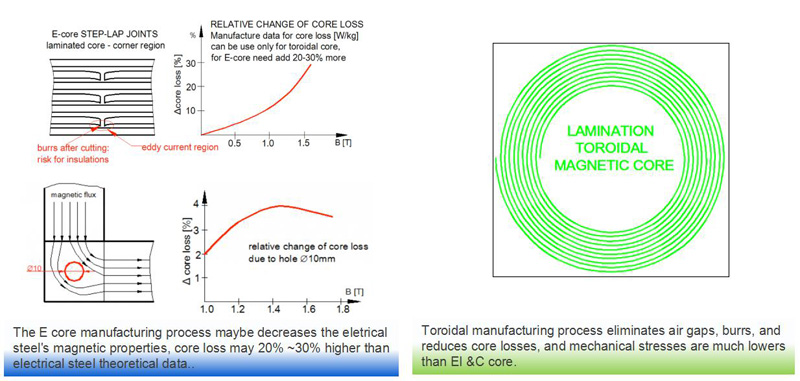

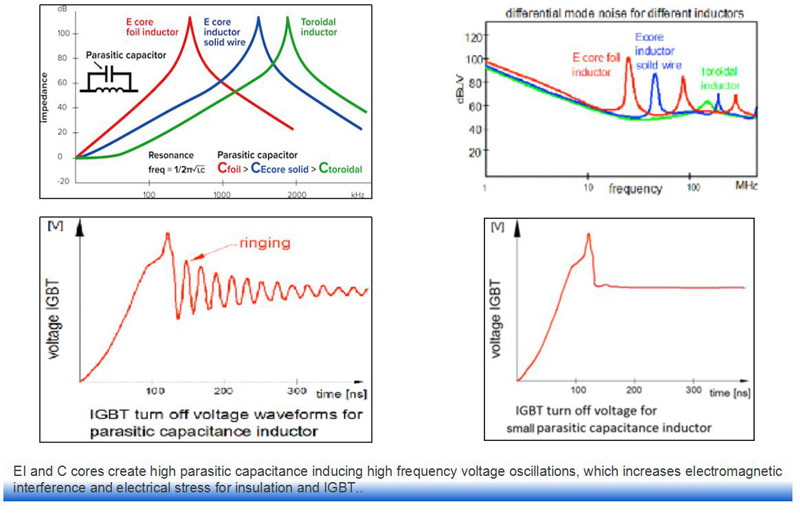

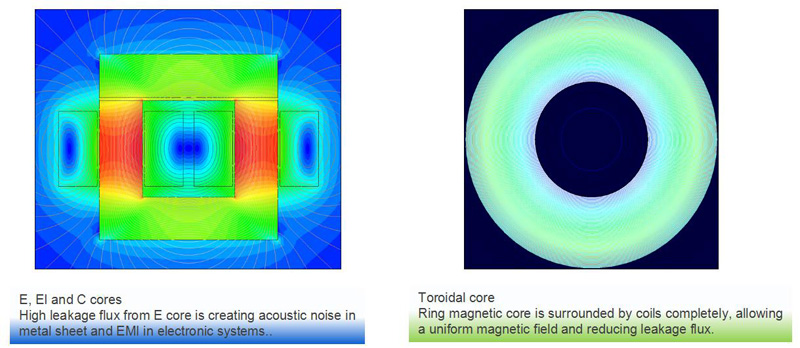

Compared the classic EI,EE,C foil inductors, Toroidal cores replacement comes more and more popular, because of:

A). LOWER PARASITIC CAPACITANCE

B). SAFER MANUFACTURING PROCESS

C) . DM NOISE POLLUTION REDUCTION & LOWER EMI ELECTROMAGNETIC INTERFERENCE

D) .LEAKAGE FLUX

Main Application:

New patterns of power consumption and generation are reshaping the way electricity distribution networks are used.

Flat Wire Toroidal Inductors are widely used as Booster Inductor & Inverter Inductor, which popular application in:

Relevant electrical parameters required for inductance design

|

No. |

Item |

Spec value (with unit) |

Remark |

|

1 |

Circuit topology form |

|

like : boost , invert, etc... |

|

2 |

Input voltage |

|

|

|

3 |

Output voltage |

|

|

|

4 |

Carrier frequency(working frequency) |

|

necessary |

|

5 |

Rate current |

|

necessary |

|

6 |

Inductance at rated current |

|

necessary |

|

7 |

Peak current |

|

necessary |

|

8 |

Inductance at peak current |

|

necessary |

|

9 |

Temperature rise requirements |

|

|

|

10 |

Cooling mode |

|

Fan cooling or water cooling |

|

11 |

Volume requirements |

|

|

|

12 |

Application area |

|

like UPS, CHARGE , ETC... |

|

13 |

Ripple requirements |

|

|

As an leading manufacturer of amorphous and nanocrystalline core products, Coilcore provides quality services to customers with high-performance products and one-stop solutions. By leaving a message below to get more details about Flat Wire Toroidal Inductor quickly!

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Call At :

Call At :

Tel : +86-20-85649266

Fax : +86-20-85649263

Email Us :

Email Us :

Email : derful@coilcore.com

Address :

Address :

A402 Zhuangyuangang Industry Park, No.186 Qishan Road, Tianhe District, Guangzhou 510663

© Copyright: 2025 Guangzhou Amorphous Electronic Technology Co.,ltd. All Rights Reserved. 粤ICP备2021057165号

IPv6 network supported