The overhead output power supply device is an open structure, with an aluminum alloy case, it's suitable for overhead transmission lines with a voltage of 35KV and above. The product obtains a low voltage and safe working power supply through the principle of electromagnetic induction, and provides electrical power to the monitoring device with the assistance of photovoltaic panels.

Key Properties:

1. Strong power supply capability

2. Integrated design

3. Conductive rubber buckle

Application:

Reference Items:

Technical Parameter

Technical Parameter

Work Power

Energy Harvesting Power Unit

Output Voltage 5V, Output Power 15W

Lithium battery

Standard Voltage 6.4V, Standrad Capacity 6AH

Power Supply CT

Energy Harvesting Capability

20A >4W 10A >1.5W

Protection Level

IP67

Inrush Current

31.25KA/4S 15KA/2S

Continuous Current

1500A

Solar Panel

Rated Power

6.0W(±5%)

Nominal Voltage

12V(±10%)

Conversion Efficiency

22%

Current Sensor

Power Frequency Current

Measurement Range: 15KA

Traveling Wave Current

Measurement Range: 5KA

Residual Risk Current

Measurement Range: 5A

Application Scope

Voltage Class

35kV and above transmission lines

Gross Weight

<5kgs

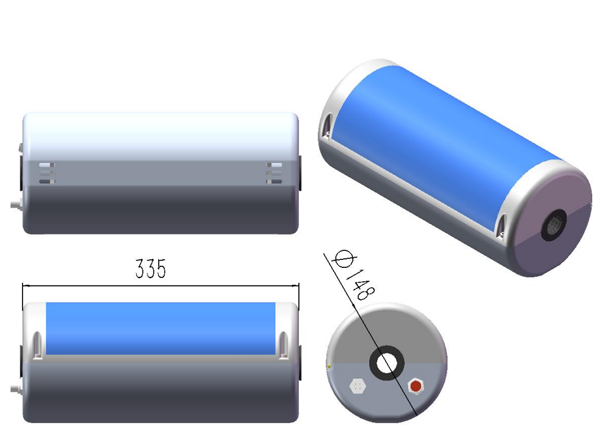

Dimension

OD 142mm, Length 315mm

Working Conditions

Ambient Temperature

-40°C ~ +85°C

Relative Humidity (RH)

1% ~100%

Altitude

≤5500m

Frequency Range: 20 ~1 K

Accuracy: <1% ±5A

Frequency Range: 1K ~ 2M

Accuracy: <1% ±2A

Frequency Range: 10kHz ~ 5MHz

Accuracy: <5% ±0.01A

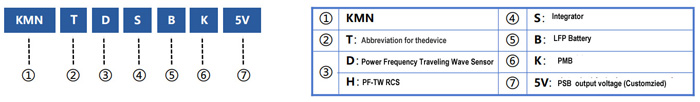

Technical Index

A). Inductive Energy Harvesting Current Transformer

1. Test with the power supply board, adjust the single current, and measure the corresponding maximum output power through electronic load.

Single Current / A

Power Output of Single CT

5A

0.37W

10A

1.29W

15A

2.58W

20A

4.16W

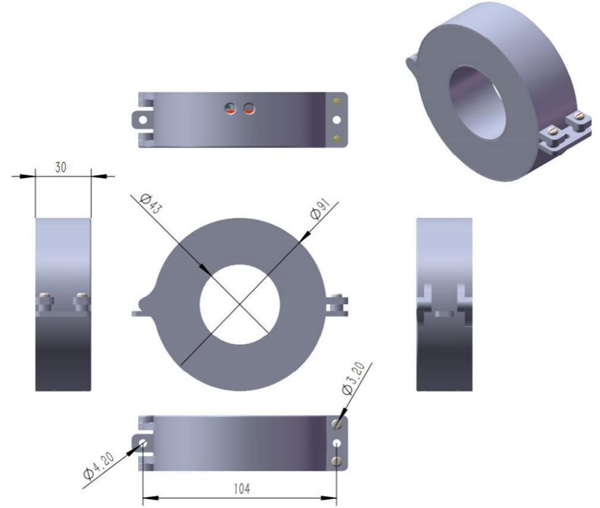

2. Inductive Energy Harvesting CT Winding Details

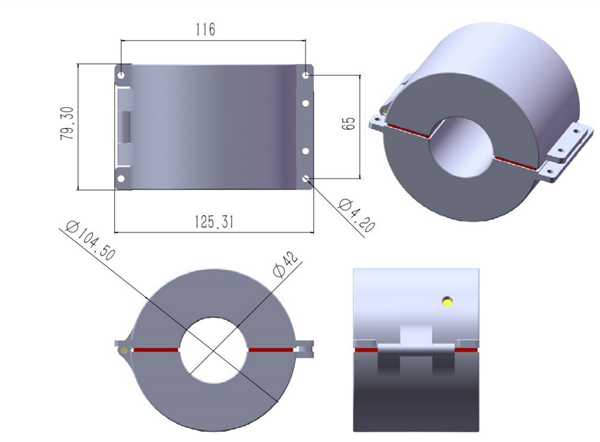

3. Inductive Energy Harvesting Dimension (mm)

1. Definition of Power Supply Board Terminals

Definition of Power Supply Board Terminals

Energy Harvesting CT Input

VH3.96 terminal, regardless of positive or negative polarity

Solar Panel Input

XH2.54-2P terminal, red positive &black negative, input voltage range o 10-24V

Adapter Input

XH2.54 terminal, the main purpose of the adapter input is to charge the battery inside the device or directly supply DC power for testing before shipment. It can also be used as a backup solar panel input in DC input lines.

Switch Interface

XH2.54-4P terminal, battery switch, S - and S+connection switches, LED and G connection switch indicator lights

Battery Interface

The battery input terminal is XH2.54, distinguishes between positive and negative poles. Rated battery voltage 7.2V, charging cut-off voltage is 8.4V. The Max. charging current 0.8A

Power board output

XH2.54-5P terminals are defined as:

+5V (DC 5V power supply)

GND (power ground)

BAT_V (battery voltage)

CF_V (photovoltaic panel voltage)

CT_V (rectified voltage after taking power from CT)

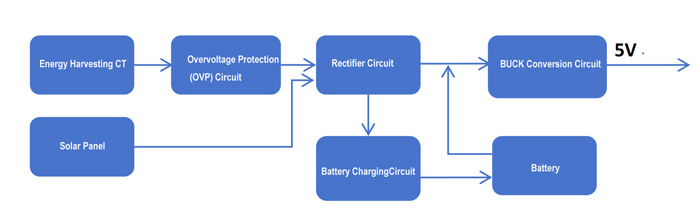

2. Energy Harvesting CT Working Principle Diagram

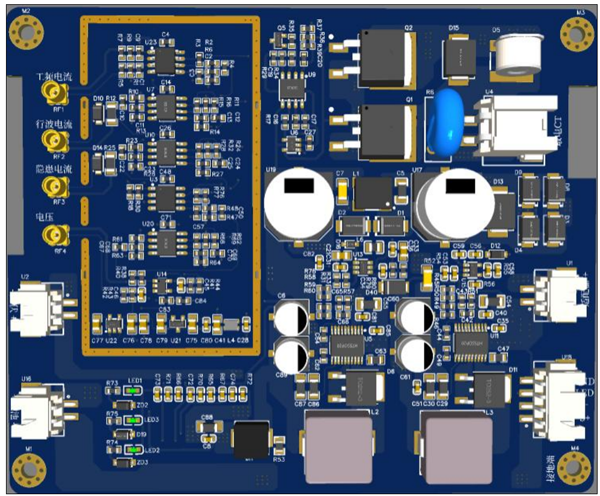

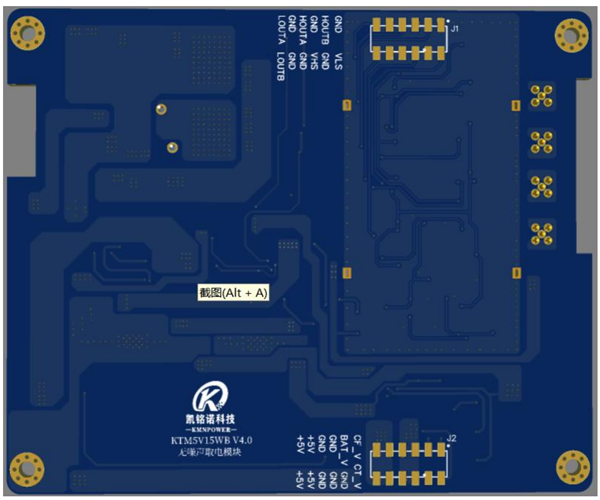

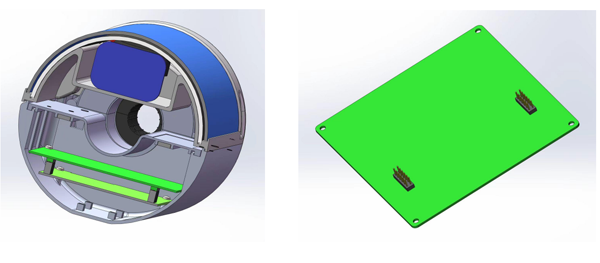

3. 3D diagram of power supply board and signal adjustment board

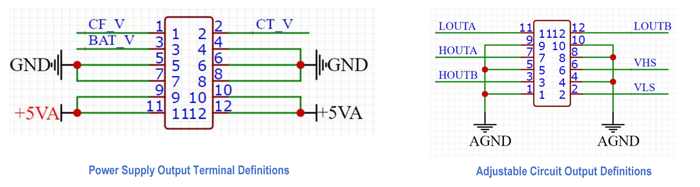

C). Pin Definition

|

Power Supply Output Terminal Definitions |

|

Adjustable Circuit Output Definitions |

||||

|

Item |

Mark |

Definitions Decsription |

|

Item |

Mark |

Definitions Decsription |

|

1 |

CF_V |

Solar Panel Voltage Divider Ratio Measurement 6.1:1 |

|

1 |

GND |

Ground |

|

2 |

CT_V |

Energy Harvesting CT Voltage Divider Ratio Measurement 31:1 |

|

2 |

VLS |

Power Frequency Voltage Output |

|

3 |

BAT_V |

Battery Voltage Divider Ratio Measurement 6.1:1 |

|

3 |

HOUTB |

Hazardous Current Output |

|

4 |

GND |

Ground |

|

4 |

GND |

Ground |

|

5 |

GND |

Ground |

|

5 |

GND |

Ground |

|

6 |

GND |

Ground |

|

6 |

VHS |

Traveling Wave Voltage Output |

|

7 |

GND |

Ground |

|

7 |

HOUTA |

Traveling Wave Current Output |

|

8 |

GND |

Ground |

|

8 |

GND |

Ground |

|

9 |

+5V |

Power Output 5V |

|

9 |

GND |

Ground |

|

10 |

+5V |

Power Output 5V |

|

10 |

GND |

Ground |

|

11 |

+5V |

Power Output 5V |

|

11 |

LOUTA |

Power Frequency Current Output (15KA) |

|

12 |

+5V |

Power Output 5V |

|

12 |

LOUTB |

Power Frequency Current Output (15KA) |

D). Power Frequency Traveling Wave Hazardous Current CT

1. Technical Parameter

Item

Power Frequency Current

Traveling Wave Current

Hazardous Current

Current Range

15KA

6KA

1mA ~ 5A

Frequency Range

20 ~1KHz

1K ~ 2MHz

10K ~ 5MHz

Accuracy

±5%±5A

±5%±2A

±10%±0.01A

Three in one integrator

Supply Voltage

3.3V

Rising Voltaeg

1.65V

Loss

~ 8mA

Corresponding output

15KA/1.1V (Valid Value)

6KA/1.5V(Peak Value)

5A/1.1V (Valid Value)

2.Terminal Remark

Default Terminal MMCX

3. CT Size (mm)

Dimension:

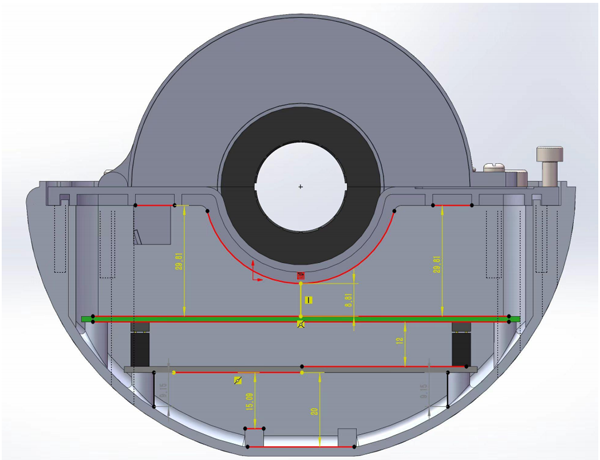

1. Complete Devise Size (mm)

2. PCB layout space

Height limited (mm)

As an leading manufacturer of induction power supply products, Coilcore provides quality services to customers with high-performance products and one-stop solutions. By leaving a message below to get more details about Inductive Power Supply Current Transformer quickly!

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Call At :

Call At :

Tel : +86-20-85649266

Fax : +86-20-85649263

Email Us :

Email Us :

Email : derful@coilcore.com

Address :

Address :

A402 Zhuangyuangang Industry Park, No.186 Qishan Road, Tianhe District, Guangzhou 510663

© Copyright: 2025 Guangzhou Amorphous Electronic Technology Co.,ltd. All Rights Reserved. 粤ICP备2021057165号

IPv6 network supported