The influence of Q value

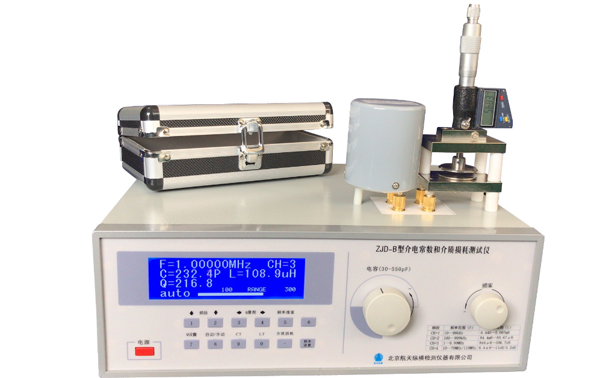

As usual, the transformer with a higher Q value, the better its quality and efficiency. Well, what should we do if the transformer's Q value is too low? What are the factors that lead to a low Q value?

As we know: Q=XL/R=2 π fL/R, where XL is the inductance, R is the loss, and f is the operating frequency. The greater the loss, the smaller the Q value will be. For example, if there is a short circuit between turns, the loss will increase, the efficiency will decrease, and the Q value will be smaller.

The occurrence of fewer strands in a multi strand wire will lead to R increasing & Q value reducing.

We usually conduct incoming material testing on multi strand lines based on this characteristic to determine their quality if any situations such as wire breakage, short circuit, etc.

The low copper purity, or enameled wires with copper-clad aluminum have increased resistance and lower Q values.

The transformer ocur virtual welding, false welding will result in an increase in resistance and a lower Q value.

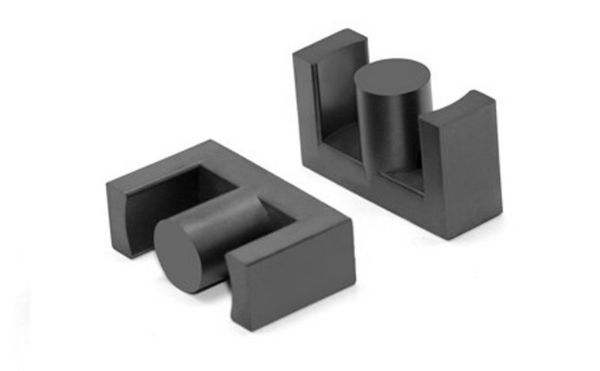

Cracking during magnetic core sintering can lead to increased losses and lower Q values. Especially when there are dark cracks in the magnetic core, the appearance cannot be determined, and it needs to be judged through Q-value testing.

The high leakage inductance of transformers can also lead to a decrease in transformer efficiency, resulting in a decrease in Q value. For inductance, the more stable the inductance, the higher the Q value. Inter layer short circuit often leads to decreased or unstable inductance, resulting in a decrease in Q value.

The frequency has a significant impact on the Q value. When testing, it is important to pay attention to the testing frequency. If the frequency is incorrect, the measured Q value will also be incorrect.

The Q value is also related to the distributed capacitance. In the case of design determination, consistency of the wire package is very important. If there is a significant deviation in the winding process, it can also lead to differences in Q values.

Previous :

1K107A & 1K107B Material For Magnetic CoreNext :

Soft Metal Magnetic Cores MaterialCategories

New Blog

Call At :

Call At :

Tel : +86-20-85649266

Fax : +86-20-85649263

Email Us :

Email Us :

Email : derful@coilcore.com

Address :

Address :

A402 Zhuangyuangang Industry Park, No.186 Qishan Road, Tianhe District, Guangzhou 510663

© Copyright: 2025 Guangzhou Amorphous Electronic Technology Co.,ltd. All Rights Reserved. 粤ICP备2021057165号

IPv6 network supported