Annealing and varnishing process of Fe82Si3.8B13.9C0.3 amorphous iron core with high saturation magnetic induction

The addition of C in the FeSiB alloy system can help to improve the amorphous forming ability, and then design high saturation magnetic flux density amorphous alloy materials, but studies have found that excessive C content will cause the soft magnetic properties of FeSiBC alloys to decrease. The low carbon content FeSiBC material system has a good application prospect in high frequency and high speed special motors because of its high amorphous forming ability, high saturation magnetic induction and excellent soft magnetic core properties.

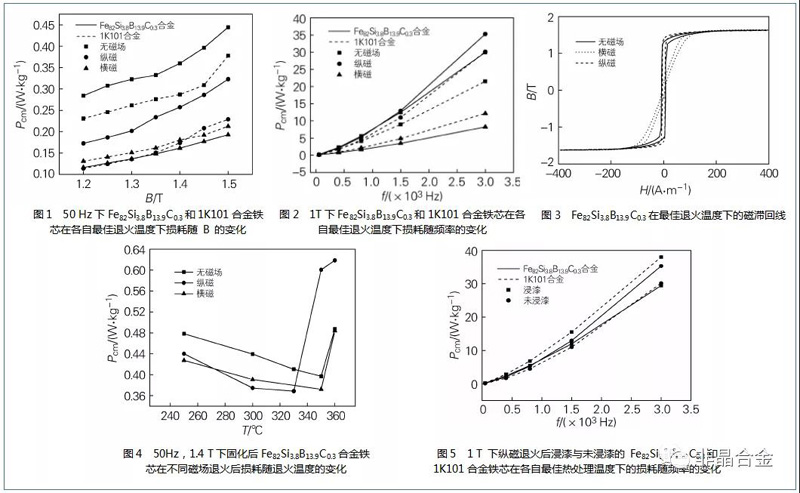

The researchers studied the annealing process and the corresponding magnetic properties of the new Fe82Si3.8B13.9C0.3 amorphous alloy strip, and discussed the soft magnetic properties and loss characteristics of the ring-shaped amorphous iron core after dipping and curing, and compared with the conventional 1K101 Amorphous alloys were compared. With the increase of the B value, the loss values of the two types of iron cores are increasing. The loss value of the Fe82Si3.8B13.9C0.3 alloy iron core without magnetic field annealing is the highest, and the loss value after transverse magnetic annealing is the lowest. The loss data of the 1K101 alloy lies between the two (Figure 1). The loss value of the two alloys increases with the increase of the frequency, and the Fe82Si3.8B13.9C0.3 alloy iron core has the lowest loss value after transverse magnetic annealing, and the highest during longitudinal magnetic annealing. During transverse magnetic annealing, the loss value of the Fe82Si3.8B13.9C0.3 alloy core is lower than that of the 1K101 alloy, and the loss difference between the two alloys increases as the frequency increases. Under the condition of f=3000Hz and B=1T, the loss value of the transverse magnetic annealing Fe82Si3.8B13.9C0.3 alloy iron core is 8.248 W/kg, which is about 32% lower than that of the 1K101 alloy (Figure 2). After longitudinal magnetic annealing, the hysteresis loop of Fe82Si3.8B13.9C0.3 alloy is rectangular, the remanence is obviously increased, and the coercive force is also lower than that of non-magnetic annealing. After transverse magnetic annealing, the obtained hysteresis loop is the most flat, the remanence and coercivity are decreasing, and it also has the characteristics of constant magnetic permeability, which can be applied to the manufacture of pulse transformers; but the iron obtained in this way The maximum magnetic permeability of the core is low, which requires a greater excitation intensity to make the magnetic induction intensity tend to saturate (Figure 3). Under the three annealing methods of no magnetic field, transverse magnetism and longitudinal magnetism, the loss of the dipping cured iron core also shows a trend of first decreasing and then increasing, and the annealing temperature at the lowest loss point is basically the same as that of the unpainted. After longitudinal magnetic annealing, the Fe82Si3.8B13.9C0.3 alloy dipped varnish cured iron core has the lowest loss at the best annealing temperature of 330℃, and its P50Hz, 1.4T=0.369 W/kg, which is higher than the loss of the unpainted iron core It is about 43% higher, and as the annealing temperature increases, the loss increases even more. The loss at 350°C is 0.601W/kg, which is about 53% higher than the unpainted iron core (Figure 4). The loss of the two alloy dipped and unpainted iron cores increases with the increase of frequency; the loss of the Fe82Si3.8B13.9C0.3 alloy iron core with longitudinal magnetic annealing and dipping curing is lower than that of the 1K101 alloy dipping iron core , P50Hz, 1.T=0.226W/kg, and the difference between the two gradually increases as the frequency increases; Fe82Si3.8B13.9C0.3 alloy iron core has a lower loss than unpainted iron when the frequency is greater than 1000Hz For the core phenomenon, under the condition of f=3000Hz and B=1T, the loss of the dipped Fe82Si3.8B13.9C0.3 alloy iron core is 29.44W/kg, which is 16% lower than that of the unpainted iron core.

Categories

New Blog

Call At :

Call At :

Tel : +86-20-85649266

Fax : +86-20-85649263

Email Us :

Email Us :

Email : derful@coilcore.com

Address :

Address :

A402 Zhuangyuangang Industry Park, No.186 Qishan Road, Tianhe District, Guangzhou 510663

© Copyright: 2025 Guangzhou Amorphous Electronic Technology Co.,ltd. All Rights Reserved. 粤ICP备2021057165号

IPv6 network supported